As manufacturing businesses move towards digital systems to expand operations and drive innovation, DevOps and automation have become more important. And the manufacturing industry has fully embraced it.

This is apparent from how DevOps exploded its worth from just $6.78 billion in 2020 to a projected $57.9 billion in 2030.

Simply put, the demand from the manufacturing industry for DevOps and automation has grown the industry by a lot.

That’s why we discuss how the manufacturing sector can further leverage the DevOps model and benefit from it in this blog.

What Does DevOps Model Mean?

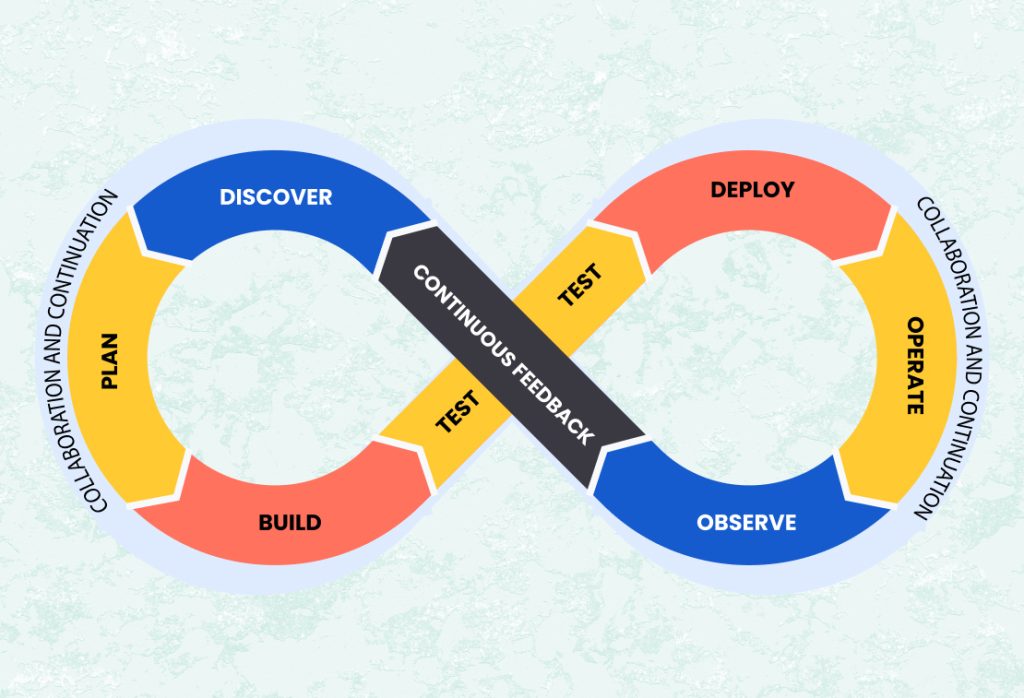

In the DevOps model, the development and operations teams work in collaboration with each other to ensure greater synergy between technology, human resource, and operations of a business.

Numerous dimensions of DevOps make it a unique model loved by businesses and brands worldwide.

- DevOps ensure a transformation in how businesses work with coding, processes, and technologies for greater efficiency.

- This business-centric practice gets better, more efficient, and value-adding with time.

- DevOps helps manufacturers innovate their services, operations, and technology rapidly. Businesses can quickly deliver market-ready products and value-adding to the users using DevOps.

- DevOps is a philosophy that encourages continuous integration between businesses, resources, and customers.

Let’s explore the core elements of DevOps to understand it better.

Related Article: Realistic Challenges Faced for Implementing DevOps in an Organization

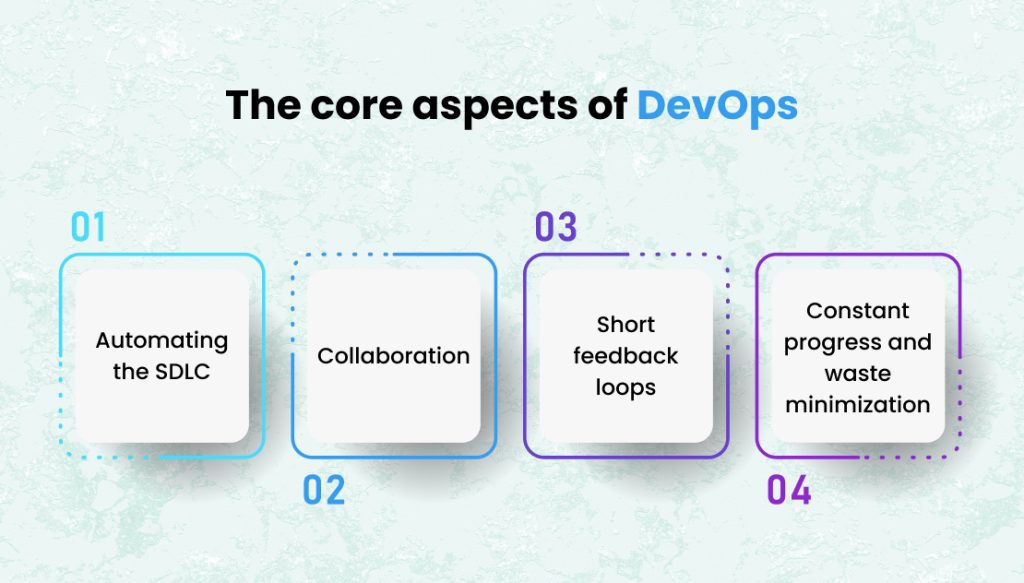

The core aspects of DevOps

We hope that you have understood what DevOps is. And now, let’s learn the core elements of DevOps that enable the philosophy to help manufacturing businesses grow faster.

Automating the SDLC

This core principle encourages businesses to automate tasks like testing, building, etc., with a higher chance of slowing down the software development lifecycle.

Collaboration

DevOps is all about collaboration between everyone involved in the process. The idea is to ensure effective and timely communication within the team so everyone knows what’s happening.

Short feedback loops

Another core principle of DevOps is short feedback loops. This makes it easier for the DevOps teams to address the customers’ demands quickly and in real-time.

Constant progress and waste minimization

Continuous improvement lies at the heart of DevOps. Excellent DevOps teams track diverse metrics and reduce inefficient and repetitive tasks to improve release time and reduce the time needed for recovery.

How Manufacturers Can Scale with DevOps and Automation?

The manufacturing industry is among the first sectors that can take full advantage of DevOps and automation. Are you a manufacturing business that wants to embrace technology and automation for better business efficiency? Here is how you can do it.

Investment and resource optimization

The global manufacturing industry is worth $40 trillion. And it is calculated that the sector produces waste of about 20%. The waste is worth $8 trillion a year. That’s a troubling figure.

However, the waste is not physical. It is more about the underutilization of resources and investments. Want to know the reasons for this wastage?

- Inefficient processes.

- Extended system downtimes.

- Unavailability of adequate data for problem-solving.

The best part of DevOps and automation is that all these issues can be resolved efficiently. Instead of the traditional siloed approach, DevOps relies on an integrated and holistic approach to ensure continuous delivery and resource optimization.

Infrastructure automation

All manufacturing businesses use complex systems, software, and processes to carry out their operations. Each system needs constant maintenance and updates to perform at its optimum level.

And DevOps can help ensure this peak performance all manufacturing businesses require from their systems.

Since automation is at the centre of DevOps, businesses can rely on automated processes to identify performance issues and bugs right at the beginning. This helps them fix the issues before it is too late.

This also helps expedite the software development lifecycle, improving product quality and reducing market time.

Better security and data privacy

The manufacturing industry is the second-most targeted sector by cyber attackers, says the Global Threat Intelligence Report 2023 by NTT Data. Hence, it would be best if you were careful when treading the technology landscape of your business.

DevOps reduces cyberattacks and empowers you for quick responses by leveraging high-quality system architecture like microservices and containers.

DevOps can play a huge role in helping you protect your business, systems, and data from exploitation.

Further, DevOps favours microservices, which limits attackers’ access due to their decentralized nature.

Innovation and future-ready products.

One of the key aspects of DevOps is progress for the future. We hope you remember this from an earlier session on this blog. As such, DevOps prepares manufacturing businesses for a much more technology-driven future.

Hence, you need to prepare yourself for system migration, eliminate monolithic and legacy systems, and embrace the cloud, if you want to take full advantage of DevOps.

With the help of DevOps, you can create high-quality and better products more efficiently, reducing wastage and improving resource utilization. And it also helps deliver impeccable, timely customer service, too.

Isn’t that what you want for your business?

Shorter recovery meantime.

Unplanned and sudden downtimes hurt businesses like no other challenges. Forbes says manufacturing businesses lose $50 billion annually due to unplanned downtimes.

And with legacy systems, fixing these downtimes can be even more challenging than with other system architectures.

DevOps can considerably reduce the occurrences of downtime. It can also reduce the time to recover from these downtimes as it enables faster response, efficient communication, and error identification.

You can also collect data about downtime and understand the underlying causes to eliminate the elements causing these issues for future safety.

Related Article: How to Do DevOps Effectively?

Case Studies of Businesses Scaling with DevOps and Automation

The advantages of adopting the DevOps model for your manufacturing business are numerous. And we know you would like to read a few examples of businesses that have done excellently after DevOps adoption.

Here are two examples that our DevOps services team personally loves.

United Airlines

United Airlines adopted the continuous testing model with their DevOps. This move helped them save $500,000 and expanded their code coverage by over 85%.

HP

In their efforts to improve the efficiency and utilization of their developers, HP carried out a study in their organization. This led them to understand that the time spent by developers on developing the code was only 5%.

The rest of the time was spent planning, deploying, and testing the codes. HP adopted the DevOps system focusing on continuous integration with continuous delivery to address this challenge.

This helped HP reduce their build cycle from 1 week to 3 hours and regression test cycle time from 6 weeks to 24 hours.

While achieving these goals is not impossible, you must work with an expert DevOps and automation consultant like AddWeb Solution to ensure success.

Challenges Businesses Face with DevOps and Automation?

While the advantages of DevOps and automation are numerous, the model has limitations. Here are a few challenges you need to tackle when adopting DevOps.

Fewer numbers of programmers

Many large startups need highly skilled DevOps engineers, which can increase the hiring cost. And if your idea is to bring your cost of operations down, there are better strategies than this.

And AddWeb Solution can help you here as we bring you talented DevOps engineers with impeccable skills and expertise.

Failing to stay updated with the latest technologies

When adopting DevOps, you need to hire DevOps experts having skills in the latest technology stacks. And this can further make adopting DevOps a challenge for most manufacturing businesses.

However, with AddWeb Solution’s DevOps services at your side, you can successfully address this issue by taking advantage of the expert DevOps engineers we offer.

Wastage of material and human resources

Many manufacturing businesses need help to optimize their human and material resources, even with DevOps, due to challenges associated with optimization.

We can help you optimize your resources thanks to our expertise in the industry.

This encourages you to scale up and down your operations, as you need, and our DevOps services can help you do that effectively.

Why Is AddWeb Solution the Best DevOps Automation Consultant?

As you have seen, DevOps and automation can transform your business quickly. It can help your business improve efficiency, take full advantage of your resources, and bolster your profitability.

However, having an expert DevOps team would be best to make all these happen. And our DevOps consulting services can help.

Here are the top reasons if you are wondering what makes our DevOps consulting service special.

A team of qualified experts

We have an exceptional team of DevOps consultants with the right qualifications and experience in the industry. Hence, all your DevOps requirements are safe in our hands.

Years of experience in the domain

AddWeb Solution has been delivering DevOps consulting services for diverse businesses for years. This experience gives us unique insights into what works and what does not. These insights help us constantly deliver value to all our clients via our DevOps services.

Multiple engagement plans

Every business is trying to achieve its unique goals. And their DevOps needs are distinct and require a unique approach. Therefore, we offer multiple engagement packages that you can use to hire DevOps experts from us.

Professional customer service

At the heart of our DevOps consultation services is top-notch customer service. Once you hire DevOps engineers from AddWeb Solution, we will provide you with all the support you need when you need it.

Industry benchmark quality

In our efforts to deliver the best DevOps solutions for our clients, we have stringent quality systems that we always adhere to. When you hire DevOps engineers from us, you also get services that match this quality.

Tailored DevOps consultation offers

When you hire DevOps engineers from AddWeb Solution, we don’t just provide services. We deliver tailored DevOps consultation services that are tailored to your requirements.

Conclusion

For manufacturing businesses, DevOps and automation bring a variety of advantages. Not only can it improve their operational efficiency, but it can also ensure optimum resource utilization and profitability down the line. Therefore, adopting these approaches is crucial for manufacturing businesses looking to grow and expand their operations. However, not all manufacturing businesses have the capability and technology infrastructure to make this happen. But AddWeb Solution can help.

At AddWeb Solution, we offer singular DevOps services for our clients. We create the offerings considering the needs and goals of each prospect to ensure maximum value for their investments. Having already worked with various manufacturing businesses from diverse sectors, we are the best in the market, where you can hire DevOps experts confidently.

If you need to hire DevOps consultants with years of experience, qualifications, and industry insights, AddWeb Solution is your best choice.