The retail and manufacturing world continues to change, and more companies are examining the internal processes they employ to boost revenues. Cutting the error margin down within a supply chain could yield substantial financial rewards in the long run, and thanks to the use of software to manage supply chains, reaping the rewards is straightforward.

Supply chain management involves complicated and intricate operations that happen simultaneously worldwide. It can be more difficult, in particular, when unpredictable events such as the pandemic and political issues arise that wreak chaos on the systems that companies have already established.

Therefore, companies are investing in different supply chain management software development to tackle the issues of managing the intricate supply chain. With the abundance of available IT alternatives, figuring out which options you need for your company isn’t easy.

Therefore, we’ve decided to compile a list of the most popular varieties of supply chain management software to help business executives think about.

So, let’s get started.

What Is Supply Chain Management Software Development?

Supply chain management software can help companies maintain track of the supply chain. It helps manage everything by allowing you to order raw materials and shipping final goods. The program tracks how much inventory you’ve got and will remind the user when to replenish your stock. It can also assist in managing and tracking orders made by customers.

Let’s take an overview of the process of managing supply chains. Naturally, managing supply chains involves many activities categorized into several major categories.

- Planning predicts future demands and develops the appropriate strategies for each area, such as sourcing supplies, scheduling employees, scheduling transportation, and more. It’s an essential stage that must be built on a complete market analysis to create precise forecasts.

- The process involves procuring the appropriate materials at an optimal cost. It’s also about selecting the right suppliers and maintaining relationships with them.

- Manufacturing involves transforming raw materials into final goods using machines, human labor, and additional external elements. Certain businesses dealing with ready-to-use products or services (like retail or eCommerce) can’t include this process in their supply chain.

- The logistics and distribution process involves negotiating with customers to arrange storage and transportation, delivering the goods, and handling returns.

- Inventory management aims to control supply levels and stock availability across the supply chain.

- Analytics is a process that runs throughout all stages and aids in controlling the performance of supply chains, identifying opportunities for improvement, and helping make the right choices.

Advantages Of Using Supply Chain Management Software

Supply chain software development is a massive benefit for any business that depends on the efficient planning and implementation of operations for long-term success and to keep an edge in the market. This is why increasing numbers of companies invest in and install supply chain software. Below are a few advantages that SCM software offers:

Improved Visibility

Being aware of what’s happening within your business’s supply chain and how it is happening is essential for efficient control of your supply chain. SCM software gives you complete visibility of your entire supply chain, offering a single overview of all your operations’ individuals, processes, and systems. The increased transparency enhances information exchange and collaboration among distributors, suppliers, and retailers, which allows businesses to assess performance at each phase in the chain.

Costs Reduced

The reduction in costs has a significant impact on your bottom line and the success of your business. The supply chain management system can help you cut expenses by cutting down on overheads related to inventory stockpiling and reducing the amount of waste generated by improving quality controls. Furthermore, keeping track of the payment process ensures that suppliers are constantly paid on time and avoid late fees; however, they can also earn discount coupons for early payments.

Analytics

Each supply chain step generates valuable data, such as raw material costs, delivery schedules, and sales numbers. Software for managing supply chains gives immediate access to this data, allowing you to keep track of the performance of your processes and make informed decisions. customer experience.

Improvement In Effectiveness

Inefficient supply chains are costly for companies. Finding and removing bottlenecks that cause delays in the supply chain process will allow you to execute faster. Additionally, integrating SCM software with existing processes and automating manual work improves efficiency and speeds up the time to market.

Greater Flexibility

Being able to see all aspects of operations in the supply chain and having access to all the related data in one location will enable you to be prepared and respond quickly to any disruptions. This will allow you to provide services to customers while earning profits.

Mitigate Risk

Many social, environmental, and other technological issues could threaten the stability of the supply chain. Monitoring and identifying these risks will allow you to know about potential problems that could affect supply, which will allow you to create an action plan to limit disruption.

Types Of Supply Chain Management Software Development

The supply chain comprises an array of different processes that transform materials into goods and then transport them to customers. The supply chain is a complex one, and many applications are used throughout it. Here is a listing of the various software developed by supply chain software development company.

Enterprise Resource Planning (ERP) Software

ERP software combines a company’s various components to create a single, centralized system. It manages inventory and customer relationships (CRM), financial plans, human resource management, and other essential business processes on a single platform. It gives the user full visibility into the company’s activities, allowing them to access current information and make choices based on reliable data.

This software plays a vital role in supply chain processes. It assists businesses in simplifying various operations, such as planning production and procurement, manufacturing, controlling stock, and managing warehouses.

Ready to transform your supply chain operations with cutting-edge ERP solutions?

Pooja Upadhyay

Director Of People Operations & Client Relations

Shipping Optimization Software

Tracking orders within a vast company can be challenging for companies that operate highly valued supply chains. If you transport multiple kinds of goods to different locations worldwide, your potential expansion is immense; however, the risk is human mistakes.

Tools for optimizing shipping can simplify this task, offering instant updates for each step of the delivery process. This way, you’ll always be aware of vital information and can swiftly react when the need arises. The majority of transport software is designed to work on smartphones, meaning executives can monitor the state of their supply chains at any moment.

We suggest looking for solutions designed to satisfy each of your distribution channel’s specific requirements and your throughput requirements. If you are shipping internationally, your software will produce documents related to customs and support for international carriers as needed.

Analytics Software

Analytics and business intelligence software are essential for the exact reason that vendor management software helps to predict the popularity of certain items. This allows companies to understand that the products will likely become well-known and don’t appeal to the typical consumer. The ware you don’t sell will not bring profits.

Software for business intelligence allows businesses to determine which wares will generate profit, adapt their workflow to present market conditions and determine if the product is appropriate to sell. We see these kinds of programs as an excellent complement to existing systems. In particular, you could integrate BI-related tools into your inventory management software to determine the most effective time to offer specific products to customers.

Sourcing And Procurement Software

One of the most critical aspects of managing your business’s supply chain is knowing suppliers’ bids and how they are evaluated. It is essential to see how much you spend on each product you purchase. The bid and spend software perform exactly as their names suggest. They assist you in automating most of the procurement procedure, which means you’ll be able to minimize the risk of mistakes and improve how you spend your money.

The tools can assess supplier bids and ensure better control over budgets and approvals for your procurement department. The most powerful bid and spending tools incorporate features for managing suppliers, like analytical tools to analyze performance.

Order Processing Software

The order processing process is software used to manage supply chains focused on handling orders efficiently and quickly. Because the speed at which new orders are handled affects customer satisfaction and revenues, this area of enterprise must operate smoothly. Many companies use these devices to speed up and automate daily work.

Warehouse Management Software

It is the ideal solution for those who want total control over the everyday operations in your facility. Processing orders, monitoring items, and tracking different warehouses using such logistic software is much simpler. It is unnecessary to manually enter details regarding the stock storage space or even use Excel spreadsheets. Everything is done automatically, and it is possible to view every detail needed, such as order details, locations, routes to the warehouse, etc. It’s all there.

Warehouse Management Software (WMS) can also be an ideal alternative to the ERP system. Software development specialists who offer integration solutions can help users seamlessly integrate the software into your business’s systems and provide application modernization assistance.

Inventory Management Software

Tools for inventory management will help you optimize the utilization of warehouse space as well as simplify the whole manufacturing planning process. It will help increase productivity and help you save costs. In evaluating this software, look for features that will help you better understand the current and anticipated demand in the supply chain. This is particularly important as supply chain disruptions are frequent.

Supplier And Customer Management Software

It is a popular choice that companies are choosing to incorporate to give more clearly the suppliers you have. By using this program, you’ll be able to obtain information about your customers or suppliers, track and evaluate performance, and reduce the risk of a potential incident. Negotiation and collaboration become more accessible, quicker, and more efficient using this CRM software. Ultimately, your company can take action and enhance another business process.

Demand Forecasting Software

Forecasting future demand is one of the best ways for information and inventory management systems to collect data. This type of projection allows businesses to take a proactive approach instead of reactive and avoid missing the opportunity to sell because they were unprepared. Tools for forecasting demand help reduce the cost of overheads and boost profits overall.

The effectiveness of demand forecasting tools is enhanced when integrated into a management tool so that the forecast is linked to information on suppliers that can provide the fastest turnaround time and the best quality, cost, and price.

Security Tools

You are advised to be attentive to security measures in modern supply chains. What is the reason for this? Many businesses working within the manufacturing industry strive to keep details concerning production as secret as possible. For instance, the information released about specific products within the mobile sector could affect its market share.

You should also consider using encryption software to secure an extensive supply chain from malignant people. A more comprehensive supply chain management system contains a variety of potential areas in which data could be leaked, which is why technologies like virtualization are vital in today’s market.

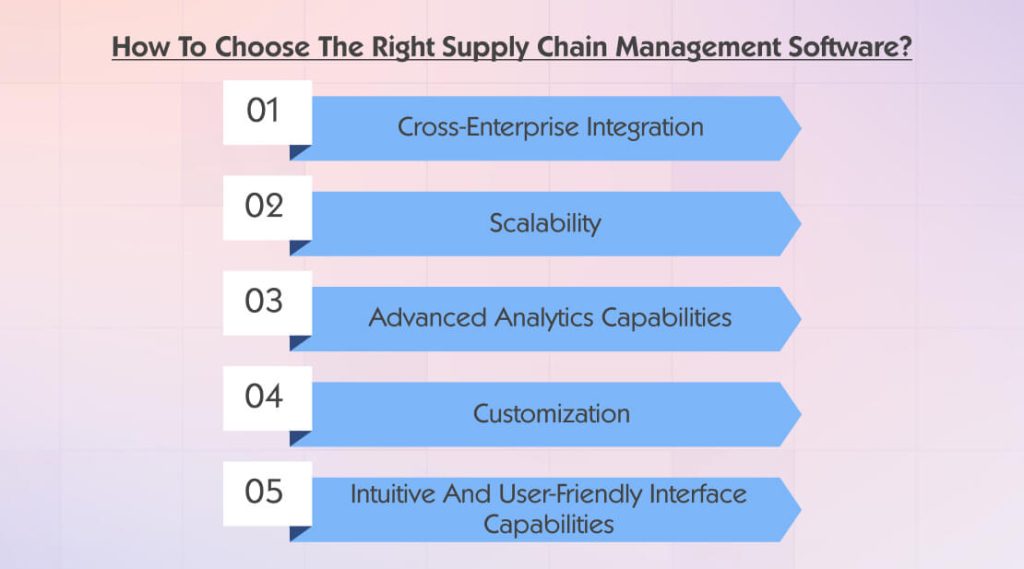

How To Choose The Right Supply Chain Management Software?

Take note of below mentioned points when you look through different supply chain management software development choices:

Cross-Enterprise Integration

When choosing the software for your supply chain, the first thing to look out for is whether it will integrate into the business processes and requirements. The supply chain software you choose must be able to seamlessly and continuously share data with you. At the same time, you work towards a common goal to facilitate collaboration and improve communications for all affected. Also, it is essential to determine if they can be integrated with your current technology platform or any other partner.

When your company expands and expands, the supply chain software will likely be incorporated into the processes you use in time. It will include equipment and features that can harm your business’s success. You must choose an application for your supply chain that can quickly integrate into your systems and help promote the transparency of your work suppliers and partners to increase your profit.

Scalability

Suppose you’re using any SCM system to run your business. In that case, the software’s capacity significantly impacts the service quality it can provide suppliers. Combining these features will help your company plan to grow more quickly through better relationships with suppliers and customers and better utilization of resources. If your application can’t expand with your company and needs to be improved, it could hinder the future growth of your business.

As technology advances at the speed of light, it’s essential to locate cutting-edge, innovative, and top-of-the-line solutions. Hence, they stay relevant for two or three years. The ability to scale your solution allows users to upgrade and update to keep up with the latest technology and prepare to meet your industry’s challenges with a stable supply chain.

Advanced Analytics Capabilities

When it comes to supply chain software, it is important to choose the right technology to track key indicators. However, you’ll be sure that it is adept at using data analytics to aid in better decisions. By utilizing advanced analytics, it is possible to access a variety of crucial features, including demand forecasts, turnover reports, customer satisfaction rates, and inventory breakdowns.

The business you run can benefit from the latest insights on the transportation of goods and services, allowing the organization to improve planning and cut costs. With this kind of data available, you can avoid being overloaded by supply chain issues and instead focus on fostering growth and efficiency.

Customization

Supply chain systems must be able to rely on a flexible method since no software can be a universal solution. By modifying the software, companies can utilize the supply chain software that meets specific industry requirements regardless of whether it’s an auto producer or pharmaceutical business.

Through a supply chain system that lets you modify alerts and queries and alter dashboards according to specific demands, organizations can regulate the flow of information and ensure that vital information is safe. Flexible software will also allow enterprises to utilize its functions to categorize, define, or distinguish their inventory.

Intuitive And User-Friendly Interface Capabilities

To simplify your business’s supply chain into a more digital context, you’ll need to use software that can take advantage of new technology, including AI and machine-learning (ML) features. The most critical aspect of high-quality inventory management software is a cloud-based system that allows your company to remain up-to-date by utilizing real-time information. A user-friendly interface makes the installation process smoother and more efficient since managers and employees can quickly master the ability to analyze and manage the information effectively.

Conclusion

The company’s supply chain management software development can be interspersed with one another or used in different ways, depending on your company’s specific situation and objectives. The information presented in this blog clearly shows that many options are available in the supply chain management software market. Every company doesn’t need to use every one of these options. We’re confident that they are all necessary and work efficiently to perform effectively in the marketplace. Reviewing your company’s strategy, defining the goals for all parties involved, and identifying the available resources are essential. This will make it much easier to decide which software version would be most suitable for your needs.

Hire our top-notch software developers to build a Bug-free custom software

Pooja Upadhyay

Director Of People Operations & Client Relations